poza= cool, to cool (swahili)

Idea:

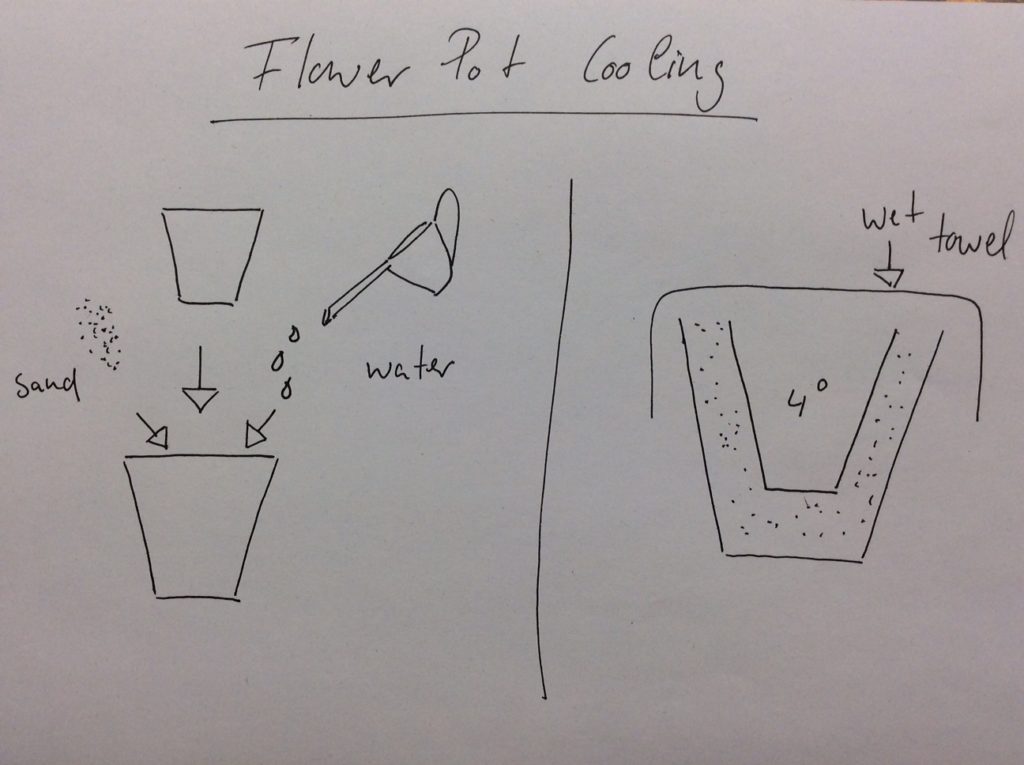

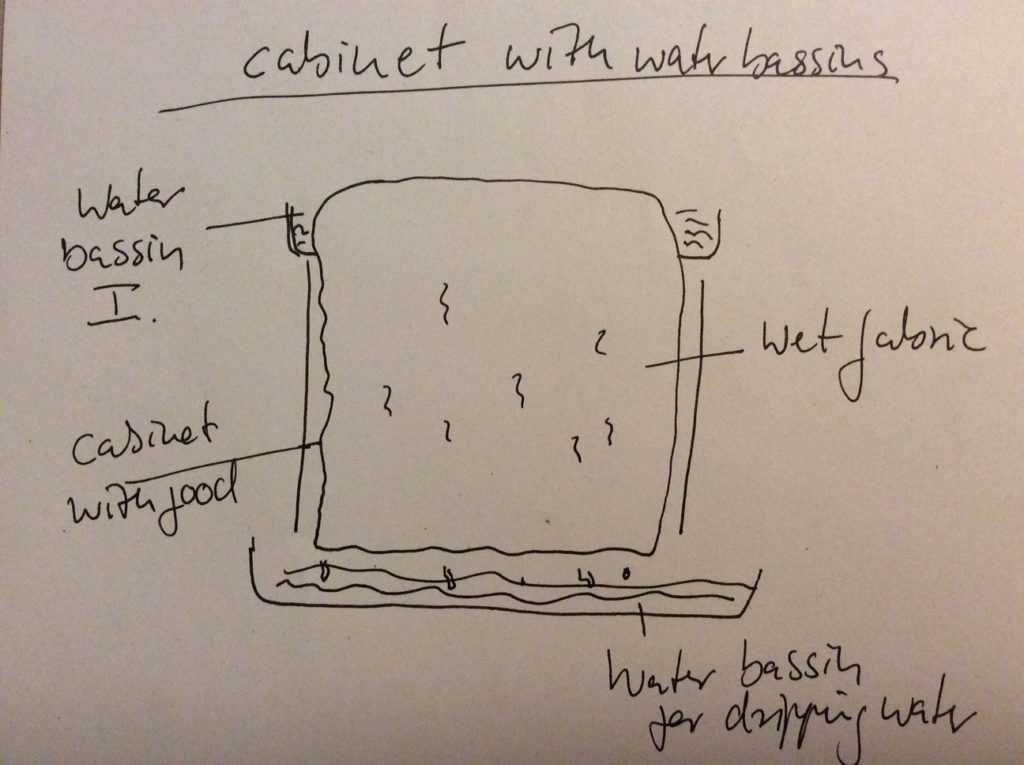

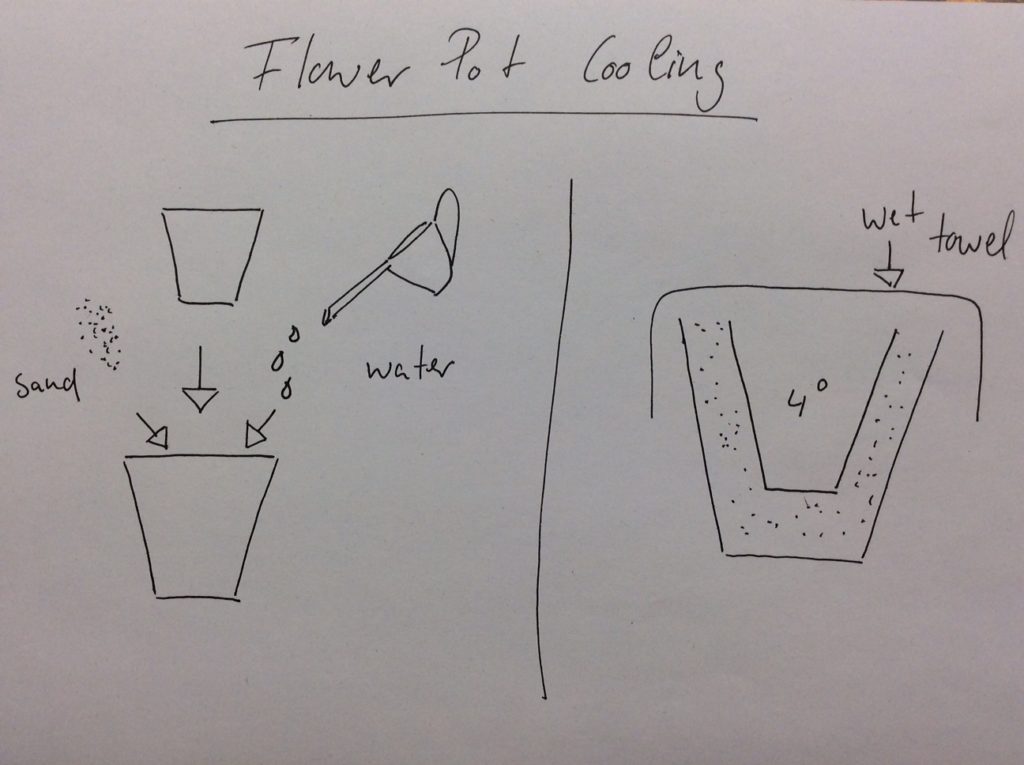

Scaling up the method of flowerpot cooling to offer people an independent cooling system for storing food and keeping it fresh. The size of the fridge should provide enough room to store an upstanding waterbottle and at least 1kg of vegetables or fruits…

Making of OCTA POZA

material:

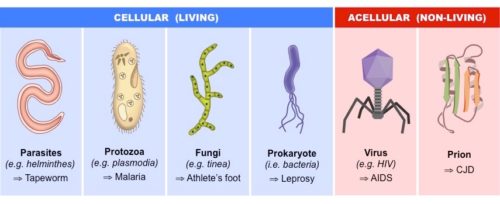

OCTA POZA consists of two clay buckets with a octagonshaped bottum. Unglazed clay in his characteristics has the ability to store moisture and is a natural product. The clay that was picked for OCTA POZA has a high percentage of grog so it can store even more humidity. Once burned, it will maintain it´s bright colour to ensure the best reflection of sunlight.

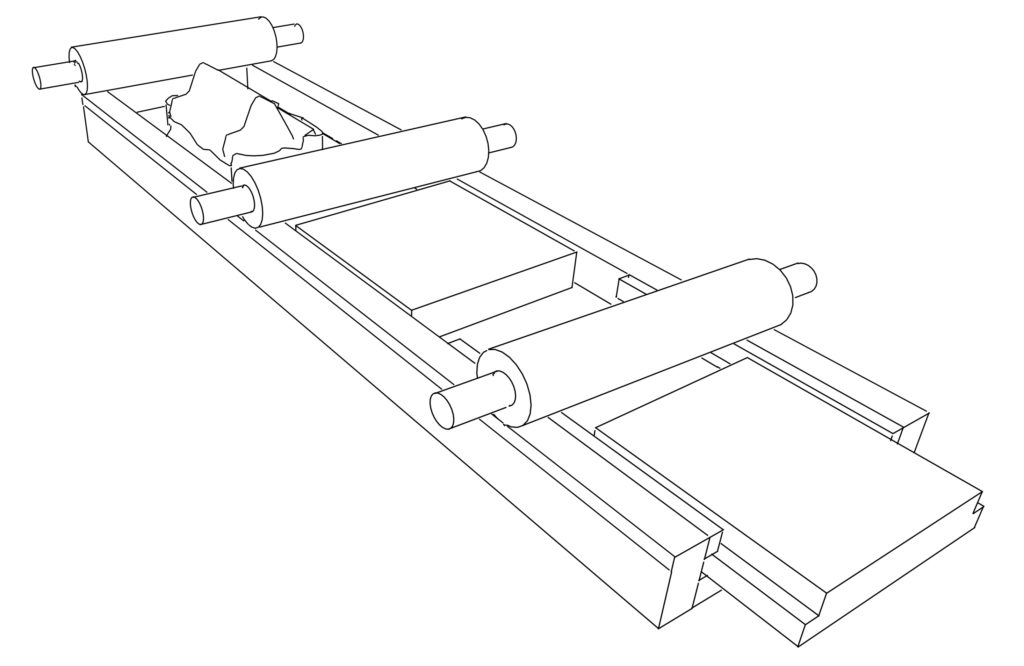

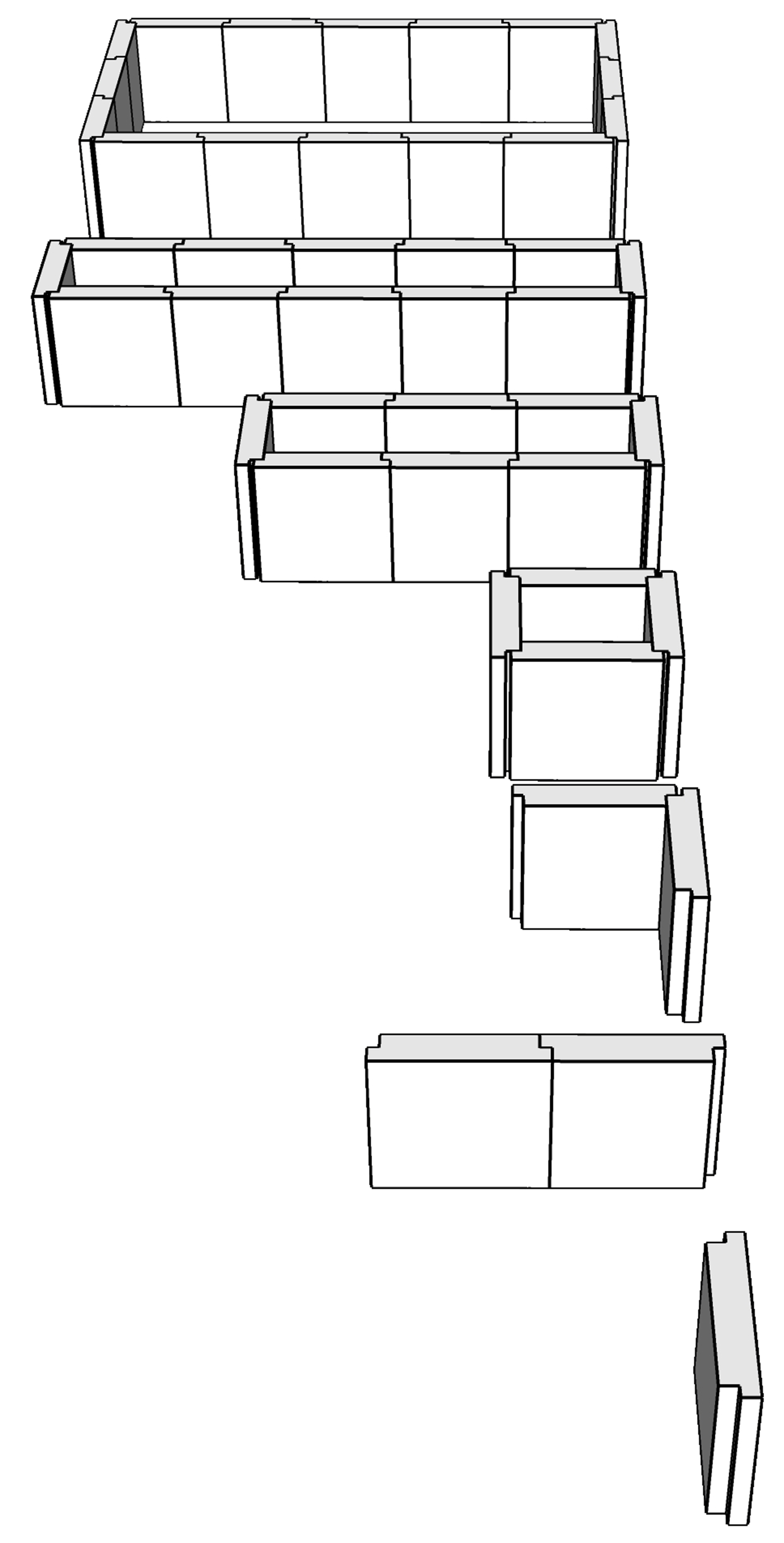

The material for the required contruction forms had to be solid to keep the clay in shape and preferably waterresistant. Nevertheless the choice was to work with wood to keep the construction convenient. To avoid swelling, the wooden planks of the bottum got coverd with plastic. For the side parts coated mdf planks did the job.

procedure:

To create a quite even surface of the vessels and to approve a constant thickness of the material, the choice for OCTA POZA´s building method was the “slab technique”.

(Detailed basic instructions for this practice under: https://www.artsy.net/article/artsy-editorial-5-ceramic-techniques-you-need-to-know )

After making sure that all air was lashed out in the clay, 16 pieces for the walls and 4 more for the baseplate were rolled out into the prepared screen of 2 cm thickness. The parts were carefully cutted out and placed aside for drying until they had reached a leatherlike texture which made the further handling a lot easier. When finally all parts were ready to be attached to each other, a mix of clay and water worked as “glue” for the joint faces. To ensure more stability to the former cracks, coils of clay were placed on each of them and firmly connected to the layers aside. The wooden profiles which got more and more closed around the vessel during the process, helped to keep the parts in position. But as soon as the the work was done, they had to be removed quickly to avoid an unbalanced drying process.

How to use OCTA POZA

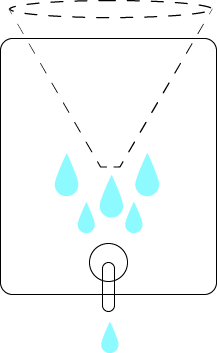

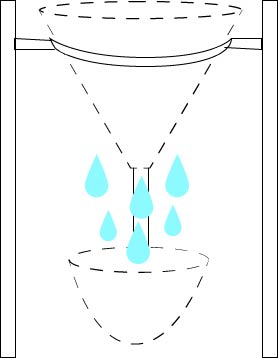

The two octagon shaped clay buckets get stacked into each other. For the use, the gap between the buckets is filled up with sand that occasionally must be watered to keep the cooling effect running. The inner bucketrim stands out to avoid that sand falls inside the bucket which stores the groceries. To increase the cooling effect, the whole system gets finally covered with a wet cotton cloth that still guarantees enough ventilation to avoid mold formation. OCTA POZA´s efficiency can be elevated if it´s habitat is shady and uncongested. The measurements of the object provide enough room to store an upstanding waterbottle and at least 1kg of vegetables.

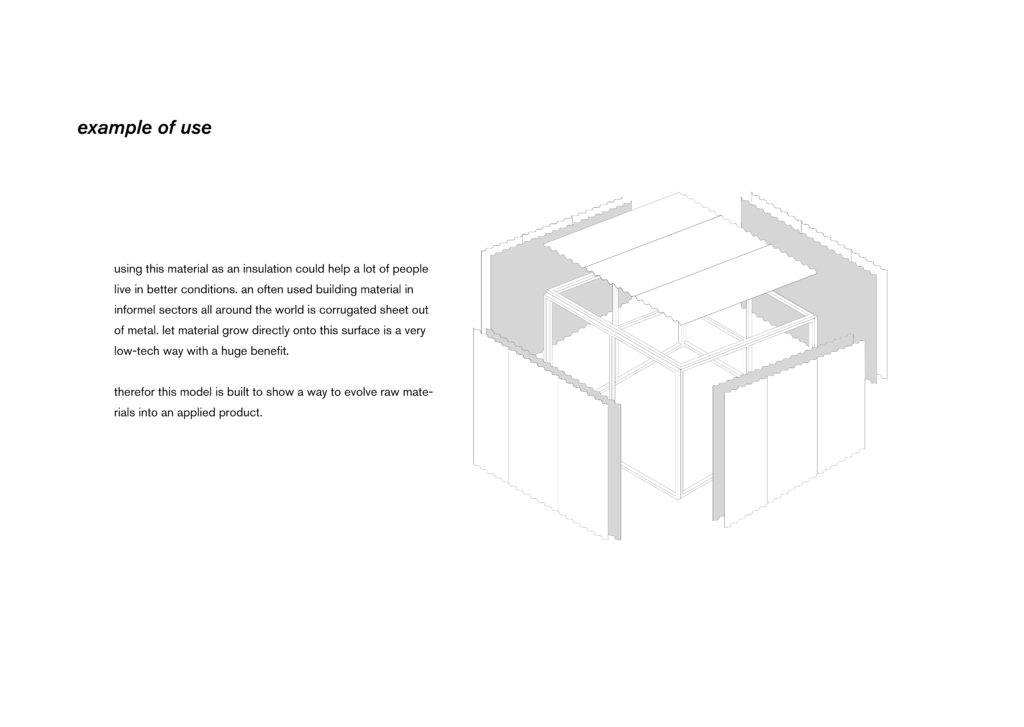

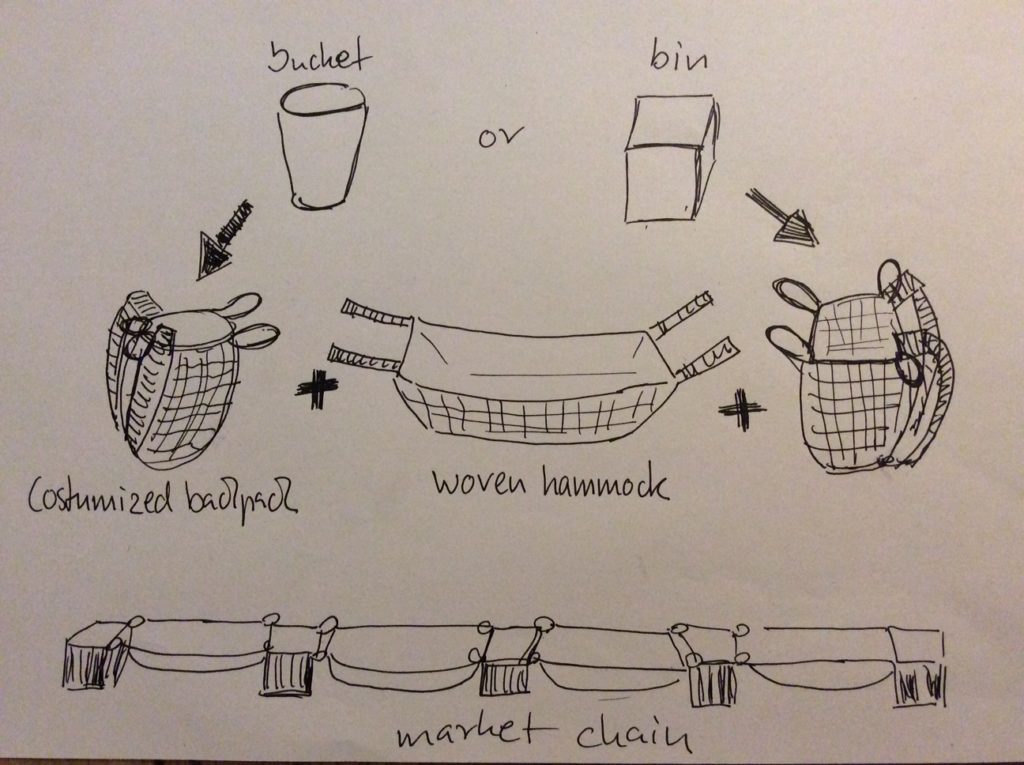

Realization in Kenia- a benefit cycle

Visions for OCTA POZA

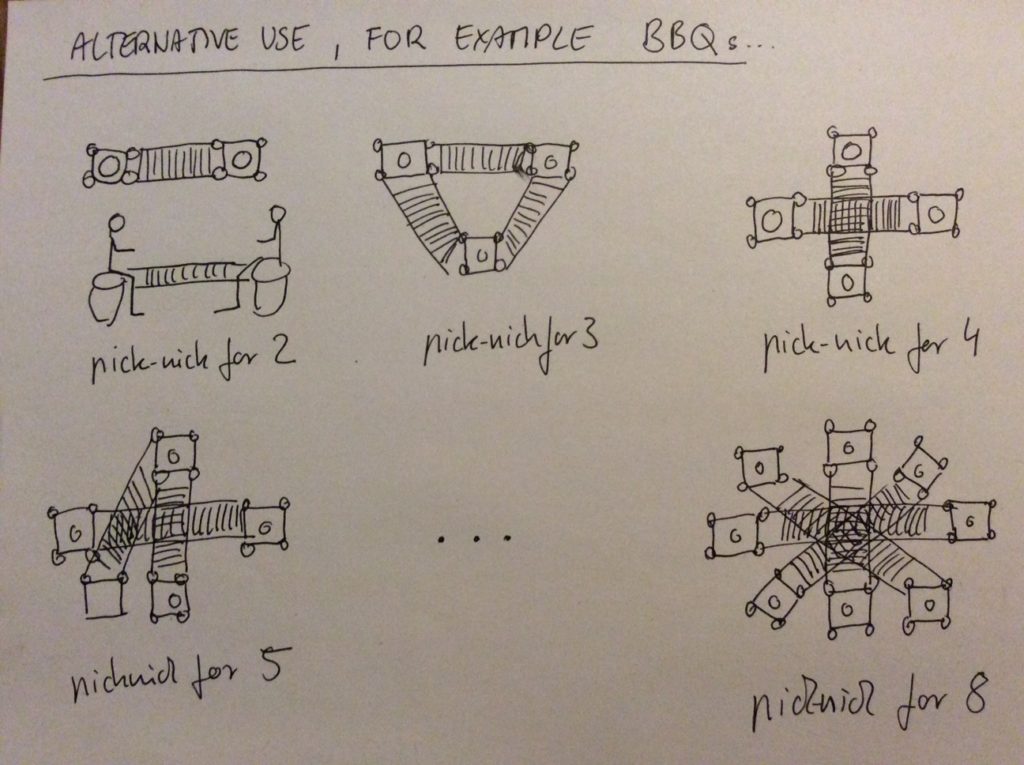

This natural fridge is designed as a DIY product. The whole process of manufacturing is determined to be copied easily with simple tools that, except for the burning procedure, allows an independent production. OCTA POZA could easily be integrated in any community. The possibility of storing food and keeping it cool is not only interesting for parts in the world which are cut off of electricity and seek for an independent solution. Also the western lifestyle could profit by this sustainable method. All it takes is peolpe who take care of it. An imaginable scenario for OCTA POZA could for example likewise be the installation in an allotment garden. Sited next to a crossing where alot of gardeners pass, this could be a set up, where leftovers from BBQs, gardenparties or plain exessive harvest crops are placed at the disposal for others to use.