DIFFERENT CONSTRUCTIONS FOR APPLICATION OF THE FILTERS:

There are different ways of using the filters.

There are tree factors to proceed from:

1: The material used for the construction should be in a material that can take some amount of water or humidity.

2. The construction should be made of out an inexpensive material, that are accessible in for example the slum areas of Nairobi.

3. It should also preferably be easy to make.

Here are som alternatives of different forms of constructions that can be interesting within there contexts:

Some of my early examples of different handles:

WHY A WORKSHOP:

A workshop (get more info here) enables for an open source climate. Since my goal is to learn about the process and the different ways of designing the filters, in order to later teach this knowledge, enabling for people to be able to make their own filters, it is important for me to get all the chances I get to try this format.

An important aspect to gain information is through different ways of input. One of these ways is through having a workshop, and thereby creating a platform for opening up for talking about these issues in general, but also gain knowledge by talking about, and maybe even question, certain aspects of the project, in order to move forward.

Also, sometimes you need to take an detour thru something else in order to be able to cross-fertilize and thereby creating a greater value within the projects. By getting feedback from other people….

By having a workshop and also making a booklet with information on how to make your own water filters, I also enable for more people to get to know about this method and maybe sharing it with others.

The method of purifying water in ceramic filters, is one of the first ways of filtering water that we as humans started using. There is written information about water filters dating as long back as we have written records, tracing back to the earliest civilizations of mankind. It has contributed to the public health evolvement, and therefore to the development of the humanity as a whole. When people could go from fulfilling the needs to fulfilling the wants.

At least 60 per cent of the adult body is made of water, and every living cell in the body needs it to keep functioning. Water acts as a lubricant for our joints, regulates our body temperature through sweating and respiration, and helps to flush waste. A human can go for more than three weeks without food, but only about a week without water (not considering factors like heat. Put that in the equation and we have a different story).

Today, 1 out of 10 people in the world lack access to clean water.

1 out of 5 deaths of children under 5 worldwide, is due to a water-related disease.

It should be a human right to have access to clean water. And it we know a way of solving the issue, why don’t learn people how to make their own and spread the knowledge? Buy using accessible cheap materials, these filters are a ideal low cost way to cleaning water for a big group of people that are otherwise at risk of getting sick or even die from drinking unclean and contaminated water.

HOW IT WORKS:

Ceramic water filters are an inexpensive and effective type of water filter, that rely on the small pore size of ceramic material to filter dirt, debris, and bacteria out of water.

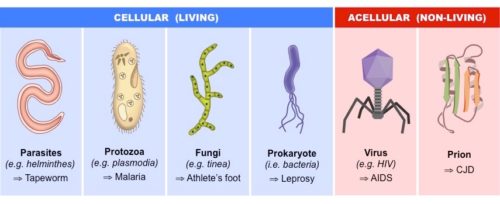

By mixing dry clay and sawdust (see more information under Clay Filters for Clean Water ~ How to mix the clay) you get fine pors in the material, where the pathogens gets stuck. If done correctly, and when also dipped into the antibacterial mixture of colloidal silver, it creates a filter that will filter the water from dangers with a 99.9% security.

WHY CLAY?

As this project is adressed mainly towards rural areas where there is a huge shortage of clean water (in this case we have a collaboration with organisations in Kenya) it is important to take notice of the accessibility and costs of these filters.

They are low cost. Pricing for ready-to-use filters, is usually between $15 to $25. Replacement clay filters will cost $4 to $6. If you take care of the filter, you could use it up to 5 years. So that could equal an amount of 40 cents/year.

Materials that are easy to access. And there are already factories in Kenya, close to Nairobi, that are working with doing these filters.

WHAT I WANT TO ACHIEVE:

KENYA: There are already factories making a standardised ceramic water filter. But those are not always the most sufficient ones, since the point of use looks different at different locations. My goal is to learn how to make the filters, to then be able to teach out the knowledge by having workshop-like lessons with the people who are in need of these, so that they then can make their own, according to their needs.

BERLIN: By starting this process in Berlin, I hope to get insights on different ways of using this method. Because, there are areas of use in the western world also. Some examples are: In boats (where the water in the tank might get contaminated), when one wants to collect rainwater or water from a lake, or for people living on the countryside that has an own well that might get contaminated. In all of these cases, the filters would have different sizes and shapes, and the ideal solution to this would be to be able to make a personalised one.

For more information and research on ceramic water filters, please klick here.

Since sawdust is mixed in the clay, it needs to do from dry to wet.

These are the ingredients that you need for making the clay are the following:

1.

Mix the sawdust with the ball clay. (Warning! Dry clay is very harmful for the lungs, you should always use a mask and do it under ventilation or outside.) Parts should be 50/50, but you could also use more sawdust and still get a good functional filter. The size on the sawdust should be quite small, a #30 (600 Micon) size sieve works best, although other sizes can work. Smaller is not advised, as it will be a slow process to sieve and will slow the filtration rate. Larger can be used, up to the size of a window screen, although the filtration quality will suffer some, since it will reduce both plasticity and strength.

2.

Add water. Just add a bit of water at a time and mix it well.

3.

Once the clay is workable, wedge it to further mix the clay and remove bubbles from the inside of the clay. Then shape into the form you want. Either just like a small bowl or by carefully smudging it in a mold. But make sure that there is no air inside, otherwise the bowl risk exploding in the oven due to air pressure. Ideal wall width should be around 0.5 – 1 cm.

4.

Fire it. A temperature around 890 degrees C is the optimal firing temperature because it creates a balance between porosity and strength. The organic material (the sawdust) will burn off, leaving behind pores for the filtration to take place.

THINGS TO BEWARE OF:

Beware of cracks. If the firing was done correctly, it should not have resulted in any significant cracks, although there may be some cracks leftover from the forming of the clay. Cracks will make any filtering done by the ceramic useless.

The clay will need to be soaked in water before it can actually filter anything, otherwise your first attempts at filtering water through will just be soaked into the body of the ceramic. Once it has been soaked, pour the water to be filtered in and place the pot over something such that it can drip out of the bottom. If you do this soaking in colloidal silver, the filter gets an even better protection.

If this process is done correctly, this filter should have the ability to filter out 95% (or up to 99% with colloidal silver) of the pathogens in the water.

WHY COLLOIDAL SILVER?

You have probably done this at one point of your life. Throwing a silver coin in a well for good luck? That’s probably is a part of old folklore, since silver has been long known for having effective antibacterial properties. That it’s colloidal means it is a mixture in which one substance of microscopical particles is suspended throughout another substance (in this case silver particles in water).

Colloidal silver is deactivating the bacteria. The quantity of colloidal silver applied per filter was more important to bacteria removal than the method of application. The best method of application is to dip it in colloidal silver for a few minutes when it’s fired. Lining the filter with colloidal silver also prevents the growth of microorganisms within the filter itself.

To go with Potters for Peace recommendations to make the ceramic filters in a more sexy design, I would want to work towards the western world, as a research for the design.

Water filters for personal use is very expensive (from 200 euros and up) and not made in very sustainable materials. To make a new design on the ceramic water filters would be a cheaper and more environmental alternative for home use.

This could for example come at use in homes that have a well that doesn’t have clean water, or in boats, where there is a risk of the water in the tank being contaminated.

CERAMIC FILTER

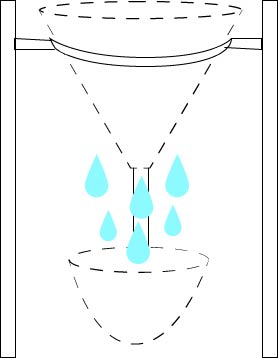

A ceramic water filter is a simple, bucket-shaped (11” wide by 10” deep) clay vessel that is made from a mix (by weight) of local terra-cotta clay and sawdust or other combustibles, such as rice husks.

When the filters are fired the milled, screened combustible material burns out, leaving porous clay walls. The filters are tested to make sure they meet a standard rate of filtration and then they are coated with colloidal silver. The combination of fine pore size and the bactericidal properties of colloidal silver produce an effective filter.

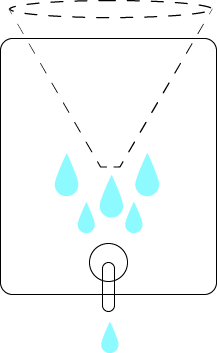

When in use, the fired and treated filter is placed in a five-gallon plastic or ceramic receptacle with a lid and faucet. Water passes through the clay filter element at the rate of 1.5 to 2.5 liters per hour.

Pricing for ready-to-use filter units, including the receptacle, is determined by local production costs and is usually between $15 to $25. Replacement clay filters will cost $4 to $6. A basic production facility with three or four workers can produce about fifty filters a day.

FACTORIES

Potters for Peace does not operate filter-making facilities or sell filters, they train others to do so, and the filter factories that they assist are run as independent businesses owned by organizations or individuals. Potters for Peace receives no financial benefit from the filter producers but filter technicians have their expenses paid and may receive a stipend while working on a new facility.

There is a local producer called Chujio Ceramics, in Limuru, 1 hour outside Nairobi.

Potters for Peace recommendations to me:

“There is always a need for sexy container designs. The filter is usually sold with a plastic bucket which has less than positive associations (trash can). I’m sure you could benefit from talking to them and getting some insight with their experience in marketing the filter.”

“We generally suggest using multiple filters for schools and other communal settings, but one of the biggest advantages of the filter is that it treats the water at the Point of Use (household or school), reducing the chance of recontamination after filtration. So there are actually advantages to keeping the filter small, portable, and in the home.”